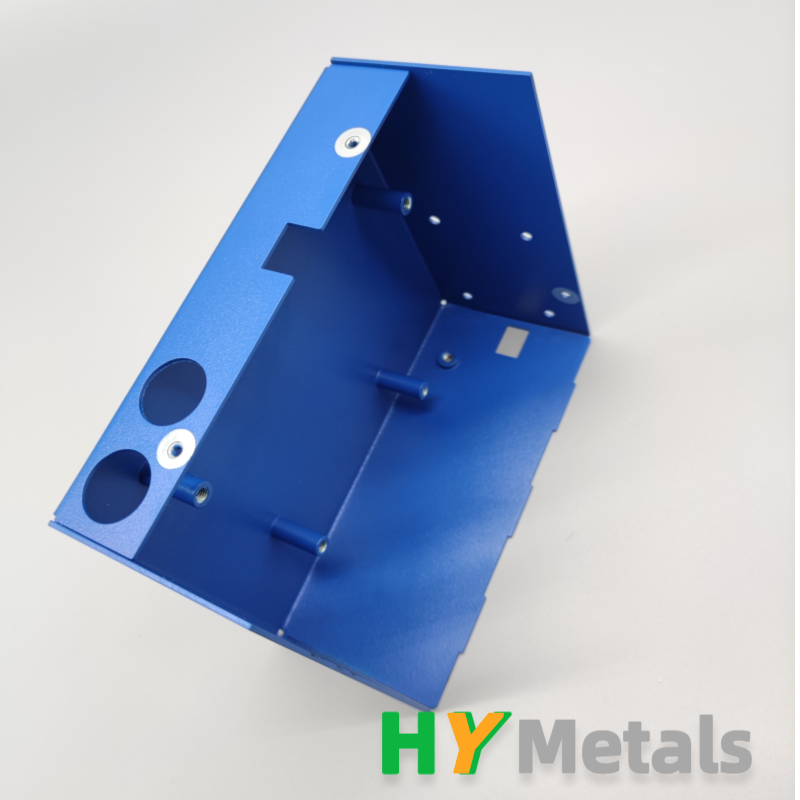

High-quality precision components for CNC machining.

By:Admin

With over [number of years] of experience in the industry, CNC Precision Components has built a solid reputation for its ability to deliver precision-engineered parts to a wide range of industries including aerospace, automotive, medical, and defense. The company’s state-of-the-art facility is equipped with the latest CNC machines and advanced manufacturing technologies, allowing it to produce complex components with tight tolerances and exacting specifications.

As part of its expansion plans, CNC Precision Components will be adding new machining centers, hiring additional skilled personnel, and implementing advanced quality control measures to ensure that its products meet the highest standards. This investment in new technology and talent will enable the company to increase its production capacity and reduce lead times, allowing it to better support its customers’ growing needs.

In addition to expanding its production capabilities, CNC Precision Components is also focusing on strengthening its global presence. The company plans to establish strategic partnerships and distribution channels in key international markets to better serve its growing customer base. By building relationships with local partners, CNC Precision Components aims to provide localized support and faster turnaround times for its customers around the world.

“We are excited about the opportunities that lie ahead for CNC Precision Components,” said [Spokesperson Name], [Job Title] of the company. “Our expansion plans will enable us to better meet the needs of our customers while solidifying our position as a leader in the precision machining industry. We are committed to maintaining the high quality and reliability that our customers have come to expect from us.”

In addition to its expansion plans, CNC Precision Components is also dedicated to maintaining its commitment to sustainability and environmental responsibility. The company is continuously looking for ways to reduce its environmental footprint, minimize waste, and optimize its manufacturing processes to operate in an environmentally friendly manner.

CNC Precision Components takes great pride in its ability to deliver high-quality precision components while maintaining a focus on sustainable and responsible business practices. By investing in the latest technology, expanding its production capacity, and enhancing its global reach, the company is well-positioned to continue meeting the evolving needs of its customers while maintaining its dedication to excellence.

About CNC Precision Components:

CNC Precision Components is a leading manufacturer specializing in the production of high-quality precision components for a wide range of industries. With a focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses in need of precision-engineered parts. With its commitment to excellence and continuous improvement, CNC Precision Components is dedicated to meeting the evolving needs of its customers while upholding the highest standards of quality and service. For more information, please visit [company website].

Company News & Blog

Unlocking the Potential of Precision CNC Turning Services for Optimal Results

Precision CNC turning is a highly advanced manufacturing process used to create complex and intricate parts for various industries such as automotive, aerospace, and medical. It is a crucial component of the manufacturing sector, and its demand is only increasing. {Company Name}, a leading provider of precision CNC turning services, has been at the forefront of this technology, providing high-quality solutions to meet the diverse needs of its clients.With state-of-the-art facilities and a team of experienced professionals, {Company Name} has been delivering exceptional results in the precision CNC turning industry. Their commitment to quality and innovation has allowed them to develop cutting-edge solutions that have set new industry standards.Precision CNC turning involves the use of computer-controlled machines to manufacture parts with a high level of accuracy and precision. These machines can perform a wide range of complex machining operations, including turning, boring, facing, threading, and grooving. The process involves the removal of material from a workpiece to create the desired shape and finish.One of the key advantages of using precision CNC turning is the ability to produce parts with consistent quality and dimensional accuracy. The computer-controlled machines ensure that each part is manufactured to the exact specifications, resulting in enhanced efficiency and reduced waste. This level of precision is critical in industries where even small deviations can have a significant impact on performance and safety.{Company Name} has established itself as a trusted partner in the precision CNC turning industry by leveraging its expertise and capabilities. They employ a comprehensive approach that ensures every project is handled with utmost care, from initial design and prototyping to final production. Their team of engineers works closely with clients to understand their specific requirements and develop customized solutions tailored to their needs.In addition to their advanced machining capabilities, {Company Name} also offers a wide range of materials to choose from, including aluminum, stainless steel, titanium, and various alloys. This diversity allows them to cater to a wide range of industries and applications, providing clients with the flexibility to select the most suitable material for their project.Furthermore, {Company Name}'s commitment to continuous improvement and investment in cutting-edge technologies has allowed them to stay ahead of the competition. They regularly upgrade their machinery and software systems, ensuring that they are always equipped with the latest tools and techniques. This dedication to staying at the forefront of technological advancements enables {Company Name} to deliver superior results consistently.In the fast-paced and evolving world of precision manufacturing, {Company Name}'s ability to adapt and innovate has been instrumental in their success. Their commitment to ongoing research and development has enabled them to explore new materials, techniques, and processes, resulting in greater efficiency and cost-effectiveness for their clients.Furthermore, {Company Name} places a strong emphasis on quality control, adhering to rigorous inspection procedures throughout each stage of the manufacturing process. This dedication to quality assurance has earned them various certifications and accreditations, further solidifying their position as a reliable and trusted CNC turning provider.As industries become increasingly reliant on precision engineering, the demand for high-quality CNC turning services continues to grow. {Company Name} continues to spearhead the industry by delivering exceptional results that meet and exceed customer expectations. With their state-of-the-art facilities, highly skilled workforce, and unwavering commitment to excellence, they are well-positioned to remain a leader in the precision CNC turning sector for years to come.In conclusion, precision CNC turning is a critical component of modern manufacturing, and {Company Name} has proven itself to be a leading provider in this field. Their commitment to quality, innovation, and customer satisfaction sets them apart from their competitors. With their advanced capabilities, comprehensive solutions, and dedication to continuous improvement, {Company Name} continues to be the go-to choice for precision CNC turning services.

Discover the Excellence of Custom Metal Work for Your Projects

[Company Name] Introduces Innovative Custom Metal Work Solutions for Wide-Ranging Industries[City], [State] - [Date][Company Name], a renowned provider of advanced metal fabrication services, proudly announces the launch of its new line of custom metal work solutions. With a deep understanding of the unique requirements of various industries, [Company Name] aims to deliver tailor-made solutions to meet the evolving needs of its clients.For decades, [Company Name] has been at the forefront of the metal fabrication industry, garnering a reputation for excellence and precision. With its state-of-the-art facilities and a team of skilled craftsmen, the company has successfully completed numerous projects across a diverse range of sectors, including manufacturing, construction, automotive, and aerospace.The custom metal work solutions offered by [Company Name] encompass a wide array of products, each meticulously designed and crafted to meet the highest standards of quality. From small intricate components to large-scale structural elements, the company's expert team can handle projects of any complexity with utmost precision and efficiency.One of the key factors that set [Company Name] apart from its competitors is its commitment to employing cutting-edge technology throughout the fabrication process. By harnessing the power of advanced software and machinery, the company ensures consistent quality, accuracy, and fast turnaround times for its custom metal work solutions. This technology-driven approach enables [Company Name] to meet the ever-increasing demands of its clients while maintaining competitiveness in the market.The team at [Company Name] understands that no two projects are alike, and as such, they emphasize close collaboration with clients to develop tailor-made solutions that precisely match their unique requirements. From concept development to final delivery, the company's dedicated staff works closely with clients, ensuring effective communication, continuous updates, and seamless execution of the project."Our goal is to provide our clients with custom metal work solutions that not only meet but exceed their expectations," said [Spokesperson], [Company Name]'s spokesperson. "We take immense pride in our ability to embrace innovation and leverage technological advancements to deliver outstanding results. Our team of highly skilled craftsmen is committed to maintaining the highest standards of quality and precision, ensuring that our clients receive superior products that cater to their specific needs."With a proven track record of delivering exceptional custom metal work solutions, [Company Name] has garnered a loyal client base consisting of industry-leading players. The company's commitment to excellence, reliability, and customer satisfaction has made it the preferred choice for clients looking for customized metal fabrication services.As [Company Name] embarks on this new venture, it seeks to expand its reach into new markets and strengthen its position as a leader in the metal fabrication industry. With an unwavering focus on innovation, quality, and customer-centric solutions, the company is well-positioned to achieve continued growth and success."By introducing our new line of custom metal work solutions, we aim to solidify our reputation as a versatile and reliable partner for clients across various industries," added [Spokesperson]. "We look forward to showcasing our expertise and demonstrating how our custom metal work solutions can enhance the performance and aesthetics of our clients' projects."About [Company Name]:[Company Name] is a renowned provider of advanced metal fabrication services. With state-of-the-art facilities and a team of skilled craftsmen, the company delivers custom metal work solutions that cater to the unique requirements of various industries. Through its commitment to technology-driven innovation, quality, and customer satisfaction, [Company Name] has become a trusted partner for clients aiming to incorporate precision metal components and structures into their projects.For media inquiries, please contact:[Media Contact][Company Name][Phone][Email]

- "Mastering the Art of CNC Milling and Turning for Precision Engineering" - "Unlocking the Potential of CNC Milling and Turning Techniques" - "Maximizing Efficiency with Advanced CNC Milling and Turning Practices" - "Exploring the World of Precision Engineering: CNC Milling and Turning" - "Revolutionizing Manufacturing with CNC Milling and Turning Technologies" - "Unleashing the Power of CNC Milling and Turning in Modern Industries" - "Mastering the Craft of Precision Engineering: CNC Milling and Turning" - "Stay Ahead in the Manufacturing Game with CNC Milling and Turning" - "Maximize Productivity with State-of-the-Art CNC Milling and Turning" - "A Deep Dive into CNC Milling and Turning Techniques for Efficient Production

Top Precision CNC Machining Parts Suppliers in China for Quality Products

China’s CNC Precision Machining Parts Industry Thrives Amidst Growing DemandChina’s CNC precision machining parts industry has been growing steadily over the past few years due to the increasing demand for such products across various industries. With this rise, hundreds of companies have emerged as prominent manufacturers and suppliers of high-quality CNC precision machining parts. One such company leading the way is WEIMI, a professional manufacturer of CNC precision machining parts in China.WEIMI is a well-known company with a reputation for reliability, high-quality products, and excellent customer service. The company has been operating in the CNC machining parts industry for more than ten years and has extensive experience and technical expertise in designing and manufacturing a wide range of CNC precision machining parts.The company has a team of experts who are skilled and experienced in using the latest technology to create top-quality products at competitive prices. They have helped WEIMI establish itself as a leading supplier of CNC machining parts, serving industries ranging from automotive, industrial machinery, aerospace, electronics, communications, and many others.WEIMI’s CNC precision machining parts production facility is equipped with the latest machinery and technology to ensure that the highest quality products are produced. The company uses advanced software and machines such as CAD/CAM, CNC lathes, milling machines, and others to produce precision components that meet the most stringent quality standards.One of the advantages of working with WEIMI is that they provide customized CNC precision machining parts to meet specific customer requirements. The company has a team of experts who work with clients to understand their needs and create products that meet those needs. This service has helped companies across various industries to improve the efficiency and productivity of their operations.As the CNC machining parts industry in China continues to grow, WEIMI is well-positioned to remain a leader in the market. The company has a proven track record of designing and manufacturing quality products that meet the changing needs of its clients. Another factor that has helped the company to grow is China’s status as the world’s largest manufacturing hub. The country has established itself as a powerhouse in the global manufacturing industry. It boasts of a vast supply chain and highly skilled labor force, making it an ideal location for manufacturing companies.China’s government has also played a significant role in encouraging the growth of the CNC machining parts industry. The government has introduced several policies aimed at supporting the development of the manufacturing industry, including tax incentives, subsidies, and other support measures. These initiatives have helped to create a conducive environment for companies such as WEIMI to thrive.Overall, the CNC precision machining parts industry in China is expected to continue seeing growth in the coming years. As the world’s major economies continue to recover from the COVID-19 pandemic, the demand for precision parts and components across various industries is expected to increase. WEIMI is poised to play an essential role in meeting this demand, thanks to its commitment to quality, innovation, and custom production of CNC precision machining parts that meet the specific needs of its clients.In conclusion, the CNC precision machining parts industry in China is thriving thanks to the growing demand for such products across various industries. WEIMI and other companies are leading the way in designing and manufacturing high-quality CNC precision machining parts that meet the most stringent quality standards. With China’s government support and the country’s status as a global manufacturing hub, the prospects for the industry remain bright.

Innovative Prototype of Next-Generation Heatsink Unveiled, Revolutionizing Cooling Technology

In the world of technology, finding ways to cool devices is an essential element in ensuring their longevity and functionality. Overheating has proven to be a significant problem, especially in more advanced computers and gaming consoles. To combat this, a company has developed a prototype heatsink that offers efficient cooling with a sleek and modern design.The heatsink prototype, which is made from high-quality materials, has been tested extensively to ensure its efficiency in cooling electronics. The prototype has been developed with an eye towards aesthetics by featuring an attractive, modern design that emphasizes functionality, with a sleek black finish that will complement any computer or gaming console.According to representatives from the company, this heatsink prototype utilizes a unique combination of materials, including aluminum, copper, and nickel. These materials help to create an efficient cooling solution that will drastically reduce the risk of overheating, enabling users to work on their devices without fear of hardware malfunction.The company behind this innovative product is a leading manufacturer of computer and gaming peripherals. With years of experience and dedication, they have gained a reputation for producing high-quality products that address the needs of tech enthusiasts and professionals alike.The company has a range of computer and gaming peripherals, including headphones, keyboards, and monitors, among others. The company has attained the trust of many users due to their ability to produce innovative and reliable products consistently.The prototype of the heatsink has been developed as a part of the company's commitment to research and development. The company stated that by investing in R&D, they could remain innovative and remain committed to developing products that meet the evolving needs of their customers.The heatsink prototype is a testament to the company’s ability to create products that are both innovative and functional while meeting consumers' needs. The company's focus on aesthetics has ensured that the heatsink is not just efficient but is also visually appealing, adding an element of style to the user's computer or gaming setup.Additionally, the heatsink's materials have been carefully selected to ensure that it is durable and long-lasting, a critical factor for computer or gaming enthusiasts who invest in high-end devices that need reliable cooling solutions.The company mentioned that the prototype is currently being tested on numerous devices. The testing process is conducted under various conditions and represents real-life scenarios to ensure the heatsink provides optimal cooling results in various environments. The company is committed to ensuring that customers receive the best product by putting the finished product through rigorous testing procedures.The heatsink prototype's benefits cannot be overstated as it solves a significant problem for the technology industry while also providing a product that is both functional and aesthetically pleasing. The product's development showcases the company's commitment to innovation, investing time and money to offer sophisticated solutions to consumers' problems.While the heatsink prototype is still undergoing testing, the company aims to release the product soon. As demand for heat sinking solutions increases, the company is well-positioned to meet consumer needs. The company has assured its customers that upon the product's release, it will be widely available globally, making it easy for consumers to access the innovative product regardless of their location.In conclusion, the company that has developed the prototype heatsink is on the path to revolutionizing the cooling solutions industry. The company's commitment to researching and developing innovative products has enabled them to address the needs of computer and gaming enthusiasts successfully. As technology continues to evolve, the company seems adequately positioned to be at the forefront of offering sophisticated solutions to users. Customers eagerly wait for the release of the heatsink prototype, which promises excellent functionality and aesthetics.

Exploring Versatile and Efficient Options for Rapid Prototyping

Rapid Prototyping Options: Revolutionizing Prototyping ServicesIn today's competitive business environment, companies are constantly pushing the boundaries of innovation to stay ahead of the curve. One critical aspect of this innovation is rapid prototyping, which is essential for designing and testing new products. To remain competitive, companies need agile and efficient prototyping services that produce high-quality, functional prototypes at a rapid pace. That's where Rapid Prototyping Options (need to remove brand name) comes in.Rapid Prototyping Options (RPO) is a leading provider of rapid prototyping services that cater to a diverse range of industries, including aerospace, automotive, medical, and consumer products. With over a decade of experience in the industry, the company has consistently provided high-quality, cost-effective prototyping services that have helped clients accelerate innovation and bring products to market faster.At the heart of RPO's success is its commitment to using cutting-edge technology and advanced manufacturing techniques in its prototyping services. The company combines traditional manufacturing methods with innovative technologies like 3D printing, CNC machining, and injection molding to produce customized, high-quality prototypes that accurately represent the final product.RPO's 3D printing capabilities are among the most advanced in the industry. The company leverages a variety of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), to produce accurate, high-resolution prototypes. These prototypes can be made from a variety of materials, including plastic, metal, and even rubber, depending on the client's specific requirements.Another critical prototyping service offered by RPO is CNC machining. The company's state-of-the-art CNC machines can produce high-quality prototypes from a variety of materials, including metals, plastics, and composites. RPO's CNC machining capabilities allow clients to produce prototypes with precise dimensions and complex geometries, making it an ideal solution for industries like aerospace and automotive, where precision and accuracy are critical.For larger production runs, RPO offers injection molding services. The company's injection molding capabilities allow clients to produce high-quality, injection-molded parts quickly and efficiently. With RPO's injection molding services, clients can avoid the high startup costs associated with traditional injection molding and quickly produce functional, high-quality parts without sacrificing quality.One key aspect of RPO's prototyping services that sets it apart from competitors is its focus on customer service. The company's prototyping experts work closely with clients throughout the prototyping process to ensure that their needs are met and their expectations are exceeded. From initial consultations to prototyping design to final production, RPO is committed to providing world-class prototyping services that meet the highest standards of quality, accuracy, and reliability.RPO's prototyping services have been critical to its clients' success, allowing them to accelerate innovation, refine product designs, and reduce time-to-market. For example, RPO's prototyping services provided critical support to a medical device manufacturer that needed to produce functional prototypes for testing their devices' safety and effectiveness. RPO's 3D printing and CNC machining capabilities enabled the manufacturer to produce accurate, high-quality prototypes quickly and efficiently, helping to reduce product development timelines and costs.Overall, Rapid Prototyping Options is revolutionizing the prototyping landscape, providing efficient, cost-effective prototyping services that enable companies to innovate at a rapid pace. With a focus on cutting-edge technology, precision, and customer service, RPO is committed to helping companies accelerate innovation, optimize product design, and bring products to market faster. Whether you're in aerospace, automotive, medical, or any other industry, RPO's prototyping services can help you take your innovation to the next level.

Maximizing Efficiency and Precision: Unlocking the Potential of Investment Casting

Prototype Investment Casting (PIC) is revolutionizing the manufacturing industry with its cutting-edge technology and innovative approach to investment casting. With a strong focus on quality, efficiency, and customer satisfaction, PIC is quickly becoming a go-to solution for businesses worldwide. By utilizing state-of-the-art equipment and a highly skilled team, PIC is able to deliver superior results and unmatched precision.PIC’s investment casting process begins with the creation of a prototype. Using advanced computer-aided design (CAD) software and 3D printing technology, the engineers at PIC are able to transform a concept into a physical model. This allows for better visualization and understanding of the final product, enabling any necessary adjustments to be made before proceeding to the casting stage.Once the prototype is finalized, PIC employs a unique investment casting method that involves creating a ceramic mold around the prototype. This mold is then filled with molten metal, which takes the shape of the prototype as it cools and solidifies. The ceramic mold is subsequently broken away, revealing the finished product with exceptional precision and surface finish.One of the key advantages of PIC’s investment casting process is its ability to produce complex and intricate parts with ease. Traditional manufacturing methods often struggle with intricate designs, but PIC’s advanced technology allows for the creation of highly detailed parts with minimal limitations. This versatility opens up a world of possibilities for industries such as aerospace, automotive, and medical, where precise components are crucial.In addition to its superior casting capabilities, PIC also places great importance on quality control. Every step of the manufacturing process is closely monitored to ensure that the final product meets the highest standards. From the initial design phase to the mold creation and casting, each component undergoes rigorous inspection and testing. This dedication to quality has earned PIC a reputation for delivering outstanding products that exceed customer expectations.Furthermore, PIC understands the importance of sustainability in the manufacturing industry. By employing an optimized production process and utilizing materials efficiently, PIC strives to minimize waste and reduce its environmental impact. The company also actively seeks out environmentally friendly materials and processes to integrate into its operations. Through its commitment to sustainability, PIC aims to contribute to a greener and more sustainable future for the industry.With its exceptional expertise and commitment to innovation, PIC has successfully served a wide range of industries, including aerospace, automotive, defense, and medical. Its ability to produce high-quality, intricate components has made it a trusted partner for many prominent companies. Whether it’s creating prototypes for new products or producing parts for existing ones, PIC’s investment casting process offers unmatched precision and efficiency.Looking ahead, PIC is continuing to expand its capabilities and refine its processes. The company invests heavily in research and development to stay at the forefront of technological advancements in the industry. By continuously exploring new techniques and materials, PIC aims to further enhance its offerings and remain a leader in investment casting.In conclusion, Prototype Investment Casting (PIC) is spearheading a new era in investment casting, delivering exceptional precision, quality, and efficiency. With its state-of-the-art technology, highly skilled team, and dedication to customer satisfaction, PIC is setting the standard for the manufacturing industry. As it continues to innovate and expand, PIC is poised to revolutionize the way products are made, offering endless possibilities for businesses worldwide.

Breakthroughs in Models and Prototypes Unveiled - Learn More Here!

[Company Name] Unveils Cutting-edge Models and Prototypes, Revolutionizing the Industry[City, Date] - [Company Name], a renowned industry leader in innovation and technological advancements, has recently unveiled a range of groundbreaking models and prototypes, poised to redefine the landscape of the industry. With a commitment to pushing the boundaries of what is possible, the company aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.At the heart of [Company Name]'s success lies a dedicated team of experts, collaborating to develop breakthrough technologies and design state-of-the-art prototypes. By leveraging their extensive knowledge and expertise, our engineers and designers have crafted a series of innovative models that showcase the company's commitment to pushing the frontiers of possibility.Among the standout models in [Company Name]'s latest lineup is the cutting-edge [Model Name]. Built with precision engineering and incorporating the latest advancements in materials science, [Model Name] boasts unparalleled performance and versatility. With its sleek design and intuitive user interface, this model revolutionizes the way individuals interact with technology, making everyday tasks simpler and more efficient.Another highlight of [Company Name]'s innovative range is the revolutionary [Model Name]. Developed to address the growing demands of the modern workforce, [Model Name] combines powerful computing capabilities with a lightweight form factor, enabling professionals to work effortlessly on the go. Equipped with advanced processors and seamless connectivity options, it represents a paradigm shift in the world of portable computing.[Company Name] has also taken significant strides in the realm of sustainable transportation with the introduction of the game-changing [Model Name]. This all-electric vehicle sets a new standard in terms of energy efficiency and environmental friendliness. With an extended driving range, fast charging capabilities, and unparalleled comfort, [Model Name] aims to accelerate the global transition to sustainable transportation, promoting a greener and more sustainable future.In addition to its groundbreaking models, [Company Name] is proud to showcase its range of cutting-edge prototypes, which offer a glimpse into the future of various industries. From advanced robotics and automation to immersive virtual reality experiences, these prototypes highlight [Company Name]'s tireless pursuit of innovation.Commenting on the recent product launch, [Company Name]'s CEO stated, "We are thrilled to introduce our latest models and prototypes, which epitomize our commitment to delivering cutting-edge solutions that transform industries and enhance the lives of consumers worldwide. Our team has worked tirelessly to push the boundaries of innovation, and we are proud to see their hard work culminate in these groundbreaking products."With its unwavering focus on innovation and a relentless drive to redefine industry standards, [Company Name] continues to cement its position as a global leader in technological advancements. With its range of exceptional models and game-changing prototypes, it is poised to reshape various industries and cater to the ever-evolving needs of consumers.About [Company Name]:[Company Name] is a renowned industry leader in innovation, known for its unwavering commitment to pushing the boundaries of what is possible. With a team of experts dedicated to developing breakthrough technologies, [Company Name] aims to revolutionize various sectors by delivering cutting-edge solutions that cater to the evolving needs of consumers worldwide.

Expert Thermal Management Consulting for High Performance Electronics

In the world of electronics, thermal management is one of the most important factors that can make or break the success of a product. When electronic circuits run, they generate heat, and if this heat is not properly dissipated, it can cause a range of problems, from degraded performance to component failure. This is where thermal management solutions come in, and Q ATS is a leading provider of such solutions.Founded with the aim of helping electronic product manufacturers bring their products to market faster, safer, and at a lower cost, Q ATS has established itself as a trusted partner for companies in a variety of industries. Whether it's designing a custom heatsink for a high-power LED light or analyzing the thermal performance of a data center, Q ATS has the expertise and experience to help clients solve their thermal management challenges.One of the key advantages of working with Q ATS is their comprehensive approach to thermal management analysis and design. Rather than simply offering off-the-shelf solutions, their team of engineers work closely with clients to understand the unique requirements of their products and design custom solutions that meet those needs. This ensures that clients get the best possible thermal performance for their products, while minimizing costs and time-to-market.Some of the services offered by Q ATS include thermal modeling and simulation, which allows them to predict the thermal performance of a product before it's even built. This can be especially valuable in applications where thermal management is critical, such as aerospace and defense. Q ATS also offers design and prototyping services, allowing clients to test and iterate on their thermal management solutions before committing to production.Another key area of expertise for Q ATS is the design and manufacture of heatsinks, which are a critical component in many electronic products. Heatsinks are used to dissipate heat from a component or circuit board to the surrounding air, and Q ATS can design heatsinks that are optimized for a specific application, providing maximum performance while minimizing weight and cost.In addition to their technical expertise, Q ATS is also committed to providing exceptional customer service. They work closely with clients throughout every stage of the project, from initial consultation to final delivery, ensuring that their needs are fully understood and met. Their team is highly responsive, with quick turnaround times and a willingness to go the extra mile to ensure client satisfaction.Overall, Q ATS is a valuable partner for any company looking to improve the thermal performance of their electronic products. With their comprehensive approach, technical expertise, and commitment to customer service, they can help clients get their products to market faster, safer, and more cost-effectively than ever before.

New Study Finds Metal Frames Are More Durable than Plastic for Glasses

article.Metal Frames - A Strong and Reliable Solution for Your Home As a homeowner, ensuring the safety and security of your family is a top priority. Furniture and fittings play a pivotal role in making your home safe and comfortable for living. Among the many types of furniture, metal frames stand out as a strong and reliable solution for your home.At Metal Frames (brand name removed), we offer a range of metal furniture that cater to a variety of needs. Our metal frames are durable, stylish, and versatile, and can be used for different settings, from dining rooms to bedrooms. Metal frames come with many benefits. Firstly, they can withstand wear and tear better than other materials. Metal is a strong and sturdy material, making it an ideal choice for furniture that needs to withstand daily use. This means they are not only durable but also require less maintenance in the long run. Secondly, metal frames offer excellent support and stability. They can support more weight than other materials, about four to five times more than wood or plastic. This makes them an ideal choice for furniture that demands more strength, such as bed frames. Additionally, metal frames come in a variety of finishes - from high-gloss polished metal to brushed steel - that can match any home interior design. This not only ensures the strength of the piece, but also adds a sleek and elegant touch to the home.At Metal Frames (brand name removed), our metal frames are crafted with precision and care. Our skilled craftsmen use high-quality material and advanced techniques to create furniture that is both functional and beautiful. Using top-grade metals, we ensure that each product is strong and long-lasting. Metal Frames offers a range of products, from bed frames to dining chairs, all made with a commitment to quality and function. Our bed frames feature robust and intricate designs that can take on more weight without compromising on comfort. They are easy to assemble and maintain, making them an excellent investment in the long run.Our dining chairs are a must-have for your next dinner party or family gathering. Available in different styles, they are comfortable, long-lasting, and stylish. They require minimal maintenance and can be customized to fit your unique needs. With considerable experience in the market, we understand the demands of the consumers and strive to provide high-quality products that cater to their needs. We use a customer-centric approach, ensuring that our products align with customer requirements. Our commitment to quality and customer satisfaction has earned us a loyal customer base. We are continuously growing and improving as a company, and we are dedicated to providing high-quality metal furniture for years to come. In conclusion, metal frames offer an ideal solution for those seeking durable and stylish furniture that can withstand daily use. At Metal Frames (brand name removed), we provide a range of products with a commitment to quality and function, crafted with precision and care. Our metal furniture is sturdy, easy to assemble, and customizable to meet your needs. Whether you need a bed frame or a dining chair, Metal Frames has you covered. Visit our website today to shop our high-quality metal furniture and to discover why we are a top choice for many homeowners.