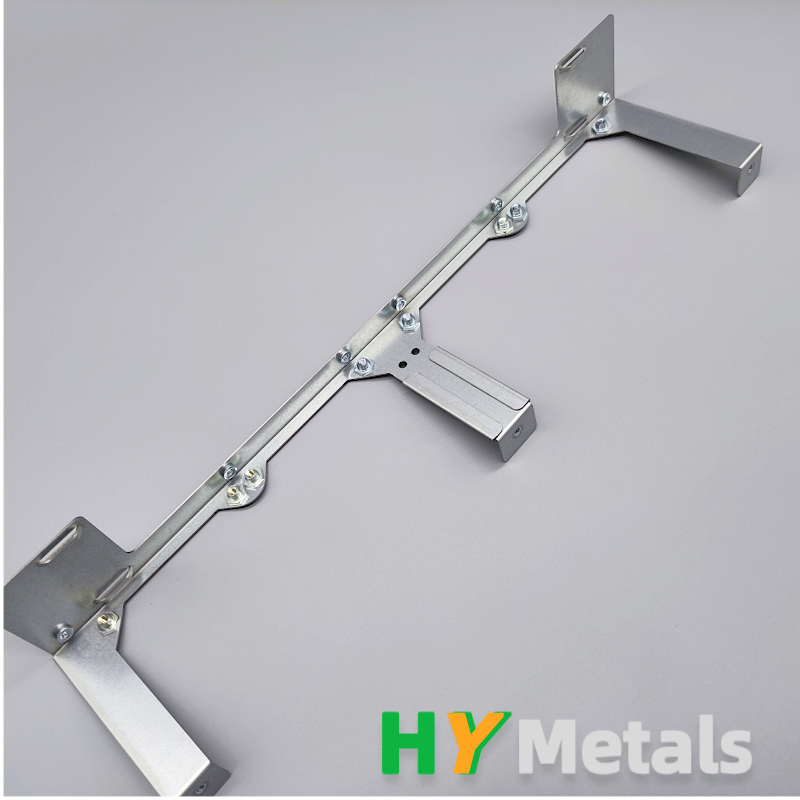

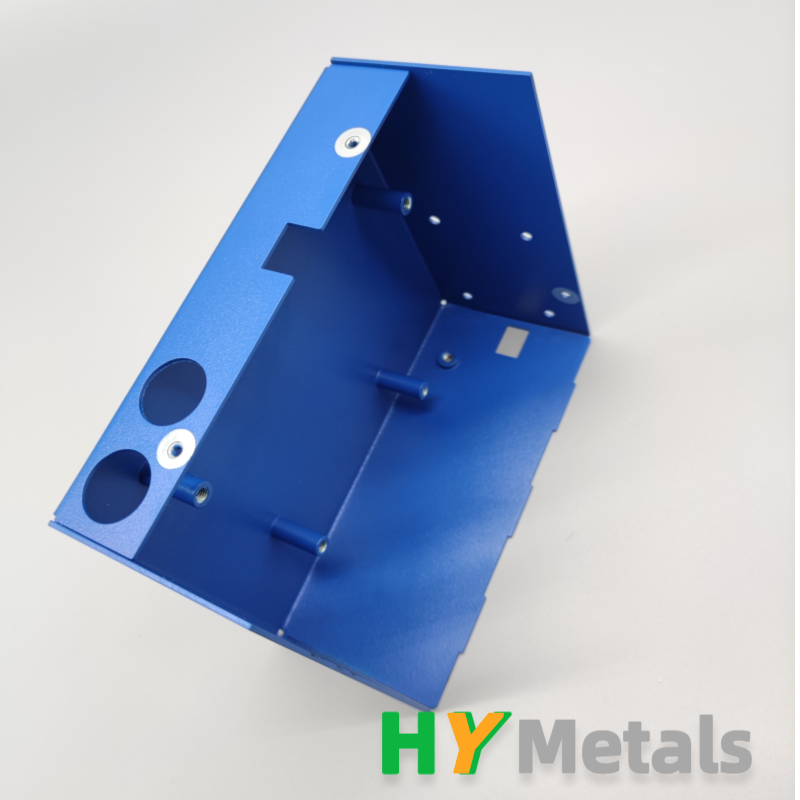

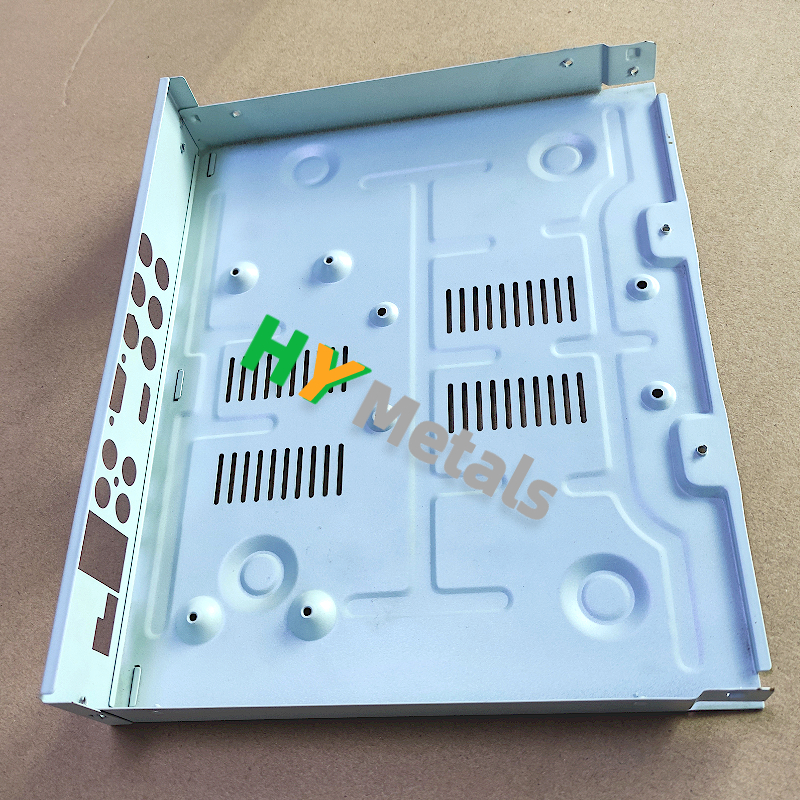

In addition to the techniques mentioned above, we also use riveting when producing sheet metal brackets. This technique is used to attach components nuts and standoffs to metal plates, providing extra strength and stability. We use high quality rivets to ensure our brackets are strong and durable. When making the sheet metal brackets for the electrical box, we also made bridge holes for the power cables to pass through. This is an essential feature of the sheet metal brackets used in electrical boxes, as it allows the wires to pass safely through the electrical box. One of the benefits of choosing HY Metals for your sheet metal support needs is that we can customize supports to meet your specific requirements. Whether you need a specific size or a specific number of bridge holes, we can manufacture brackets to your specifications. When it comes to sheet metal brackets for electrical boxes, quality is critical. With HY Metals you can be confident that you are getting a high quality sheet metal part made from galvanized steel, stainless steel or aluminum alloy. Our superior manufacturing techniques and attention to detail ensure our stands are strong, durable and free from defects. If you need sheet metal brackets for precision distribution boxes, look no further than HY Metals. Our expertise in sheet metal production, coupled with our commitment to quality, ensures that you will receive a bracket that exceeds your expectations. Whether you need a single prototype or thousands of units, we can produce a sheet metal part to meet your needs. Contact us today to learn more about our sheet metal solutions.

In addition to the techniques mentioned above, we also use riveting when producing sheet metal brackets. This technique is used to attach components nuts and standoffs to metal plates, providing extra strength and stability. We use high quality rivets to ensure our brackets are strong and durable. When making the sheet metal brackets for the electrical box, we also made bridge holes for the power cables to pass through. This is an essential feature of the sheet metal brackets used in electrical boxes, as it allows the wires to pass safely through the electrical box. One of the benefits of choosing HY Metals for your sheet metal support needs is that we can customize supports to meet your specific requirements. Whether you need a specific size or a specific number of bridge holes, we can manufacture brackets to your specifications. When it comes to sheet metal brackets for electrical boxes, quality is critical. With HY Metals you can be confident that you are getting a high quality sheet metal part made from galvanized steel, stainless steel or aluminum alloy. Our superior manufacturing techniques and attention to detail ensure our stands are strong, durable and free from defects. If you need sheet metal brackets for precision distribution boxes, look no further than HY Metals. Our expertise in sheet metal production, coupled with our commitment to quality, ensures that you will receive a bracket that exceeds your expectations. Whether you need a single prototype or thousands of units, we can produce a sheet metal part to meet your needs. Contact us today to learn more about our sheet metal solutions.Custom galvanized steel sheet metal brackets for Electrical Boxes

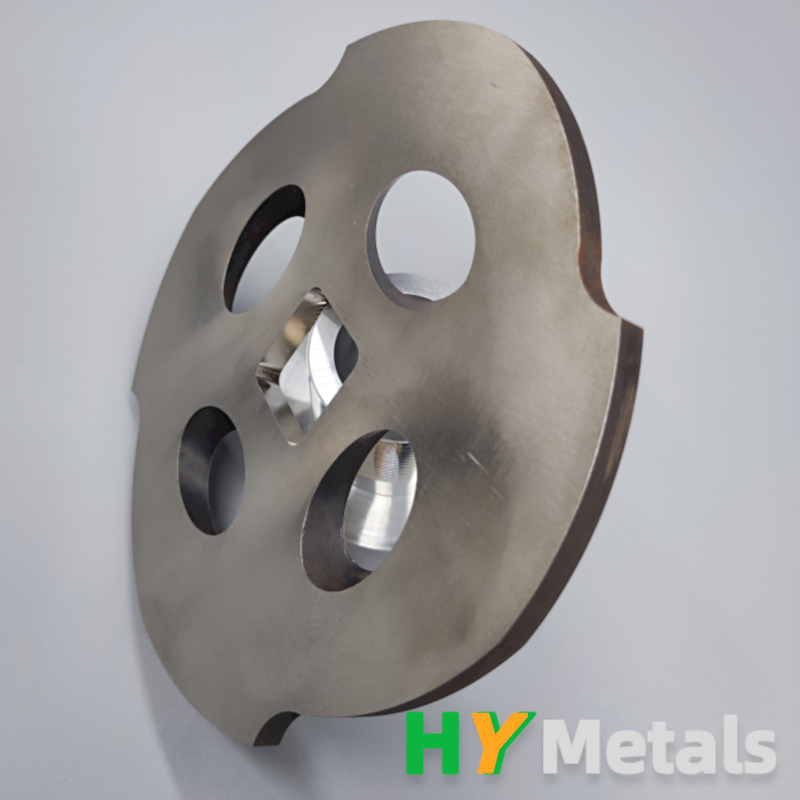

Looking for custom galvanized steel sheet metal brackets for electrical boxes? Look no further! Our factory creates high-quality, durable brackets that fit your exact specifications.

Request a QuotePRODUCTS DETAILS

In addition to the techniques mentioned above, we also use riveting when producing sheet metal brackets. This technique is used to attach components nuts and standoffs to metal plates, providing extra strength and stability. We use high quality rivets to ensure our brackets are strong and durable. When making the sheet metal brackets for the electrical box, we also made bridge holes for the power cables to pass through. This is an essential feature of the sheet metal brackets used in electrical boxes, as it allows the wires to pass safely through the electrical box. One of the benefits of choosing HY Metals for your sheet metal support needs is that we can customize supports to meet your specific requirements. Whether you need a specific size or a specific number of bridge holes, we can manufacture brackets to your specifications. When it comes to sheet metal brackets for electrical boxes, quality is critical. With HY Metals you can be confident that you are getting a high quality sheet metal part made from galvanized steel, stainless steel or aluminum alloy. Our superior manufacturing techniques and attention to detail ensure our stands are strong, durable and free from defects. If you need sheet metal brackets for precision distribution boxes, look no further than HY Metals. Our expertise in sheet metal production, coupled with our commitment to quality, ensures that you will receive a bracket that exceeds your expectations. Whether you need a single prototype or thousands of units, we can produce a sheet metal part to meet your needs. Contact us today to learn more about our sheet metal solutions.

In addition to the techniques mentioned above, we also use riveting when producing sheet metal brackets. This technique is used to attach components nuts and standoffs to metal plates, providing extra strength and stability. We use high quality rivets to ensure our brackets are strong and durable. When making the sheet metal brackets for the electrical box, we also made bridge holes for the power cables to pass through. This is an essential feature of the sheet metal brackets used in electrical boxes, as it allows the wires to pass safely through the electrical box. One of the benefits of choosing HY Metals for your sheet metal support needs is that we can customize supports to meet your specific requirements. Whether you need a specific size or a specific number of bridge holes, we can manufacture brackets to your specifications. When it comes to sheet metal brackets for electrical boxes, quality is critical. With HY Metals you can be confident that you are getting a high quality sheet metal part made from galvanized steel, stainless steel or aluminum alloy. Our superior manufacturing techniques and attention to detail ensure our stands are strong, durable and free from defects. If you need sheet metal brackets for precision distribution boxes, look no further than HY Metals. Our expertise in sheet metal production, coupled with our commitment to quality, ensures that you will receive a bracket that exceeds your expectations. Whether you need a single prototype or thousands of units, we can produce a sheet metal part to meet your needs. Contact us today to learn more about our sheet metal solutions.Hot Products

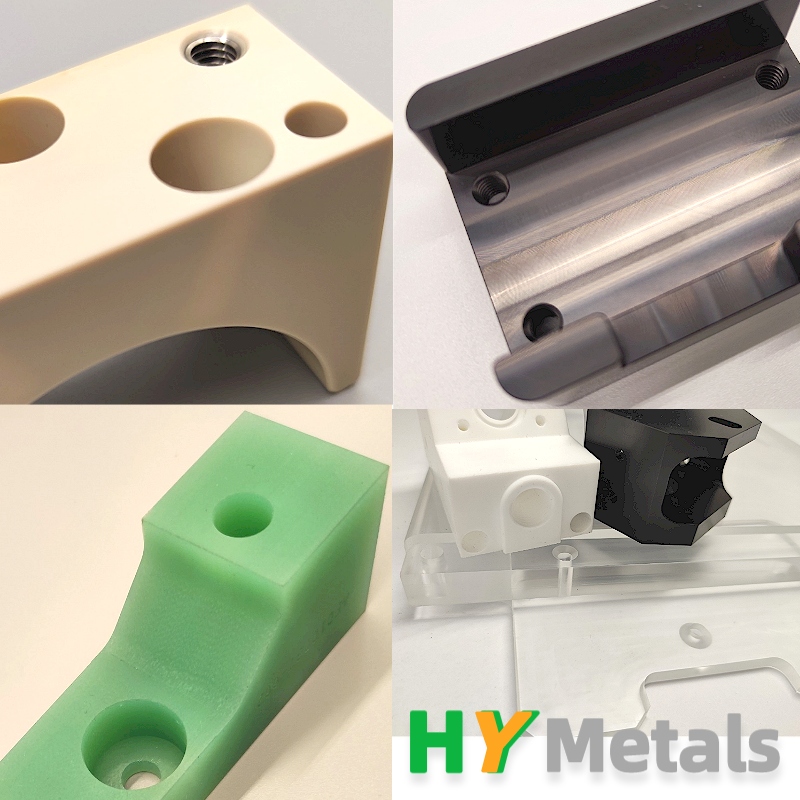

Urethane casting for rapid prototypes and low volume production

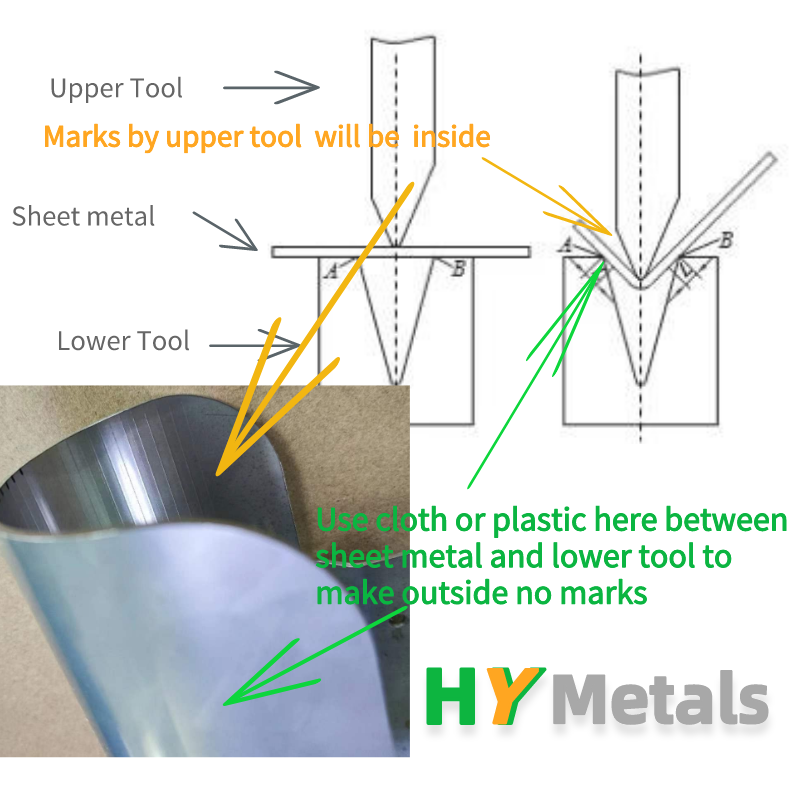

Precision Sheet metal bending and forming process

High precision OEM CNC machined camera component camera prototype parts

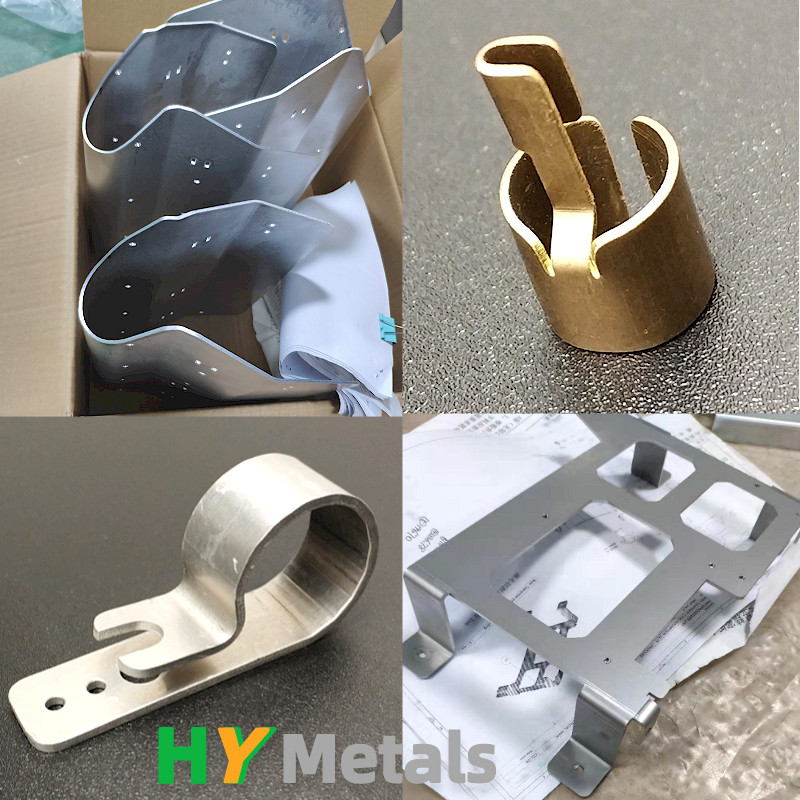

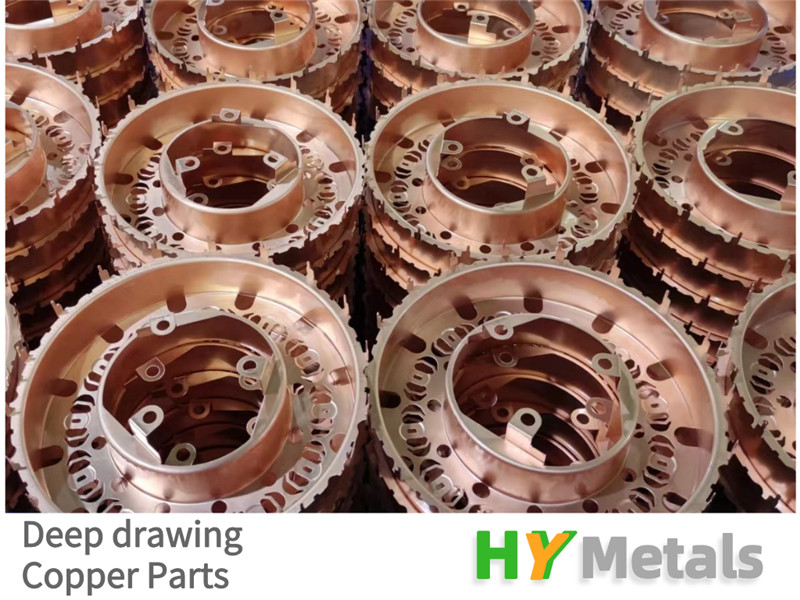

High precision metal stamping work include Stamping, Punching and Deep-Drawing

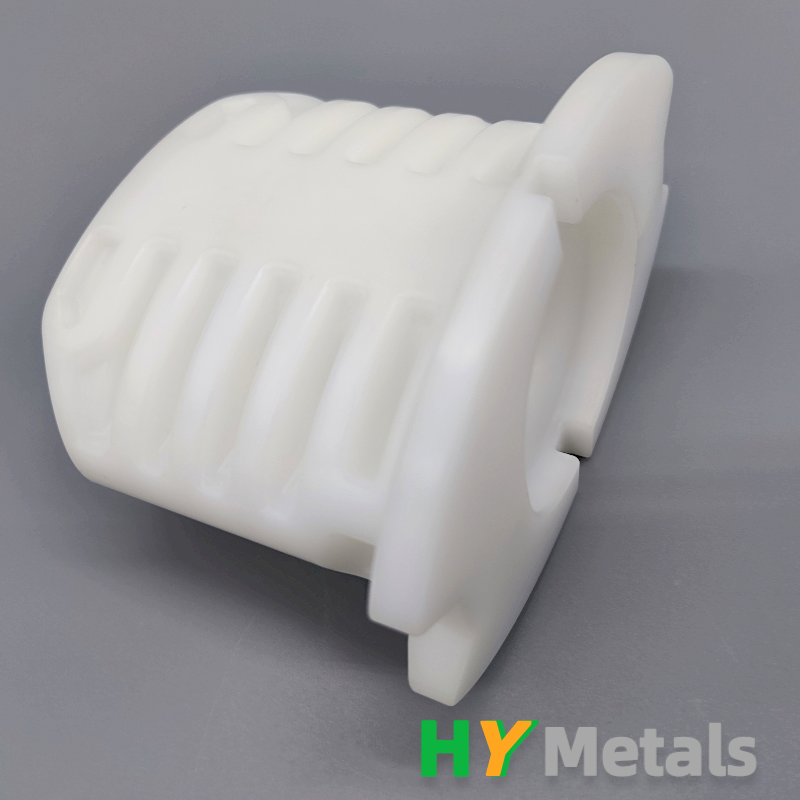

High Quality Custom CNC Machining Plastic Parts OEM POM Components

Customized metal parts which require no coating in specified areas

High Precision Plastic Parts custom machined plastic parts

Stainless steel sheet metal Camera Housing free from bending marks

High precision sheet metal formed part that features powder coating and screen printing

CNC Machining of 17-7 PH Stainless Steel: Best Precision Wire EDM

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours